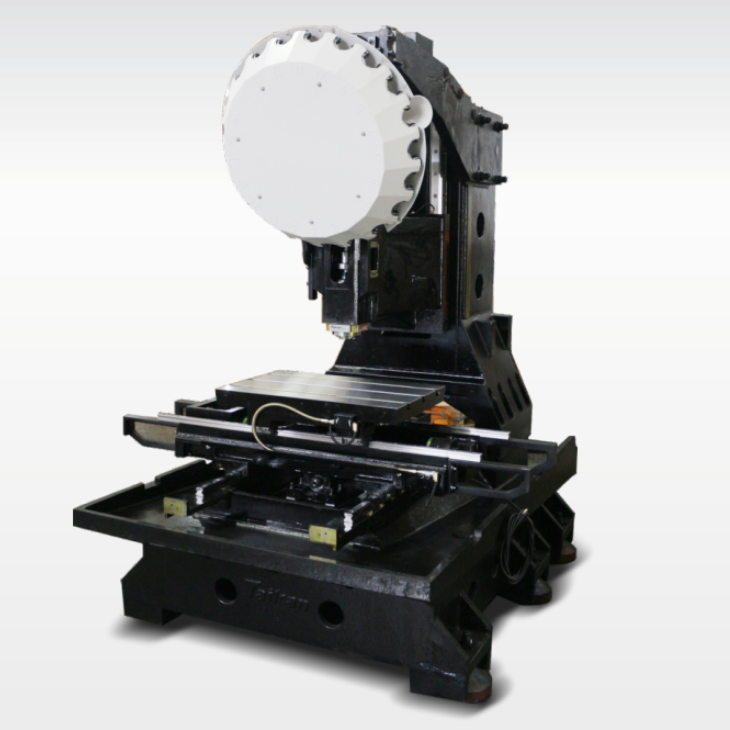

T-500S Drilling and Tapping Machine Center

T-500S Drilling and Tapping Machine Center, 3 axis milling machine center, CE, ISO Certificate

Send InquiryProduct Detail

Product Description

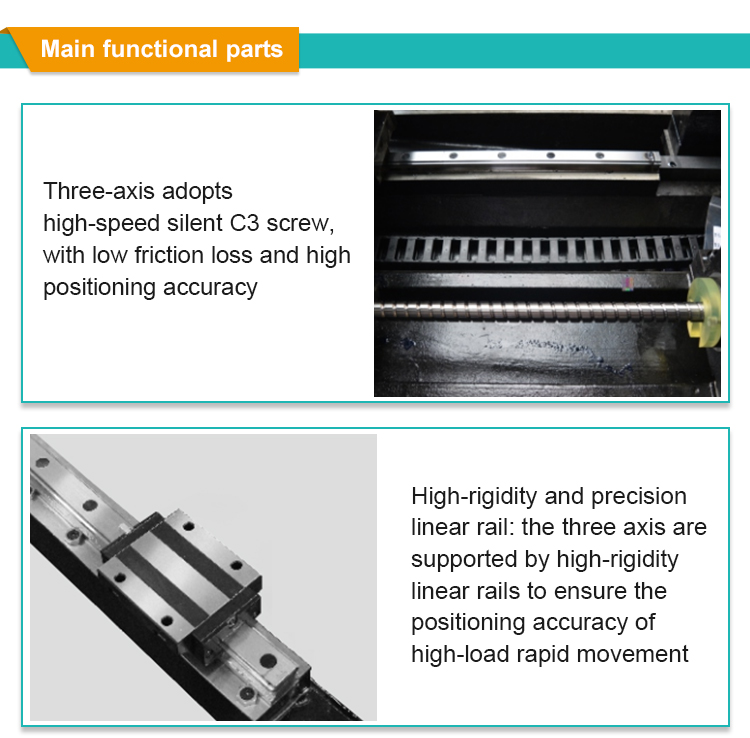

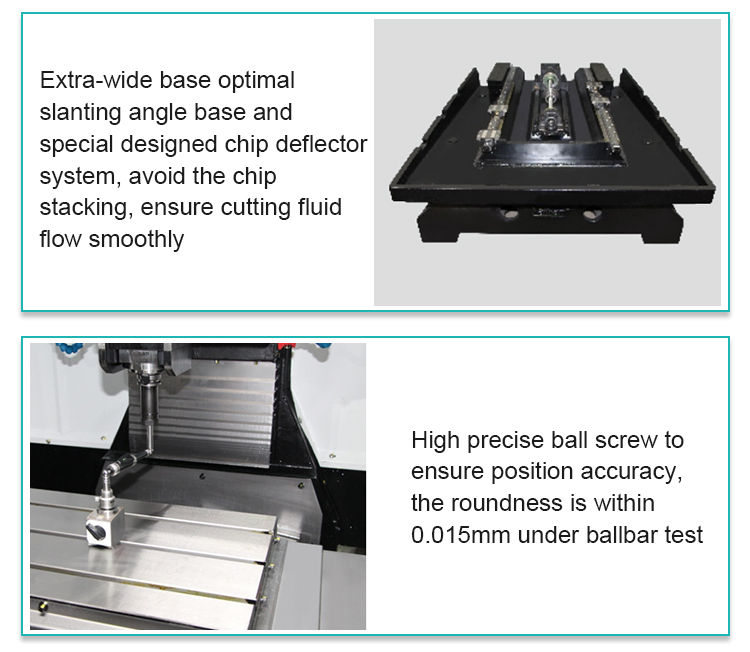

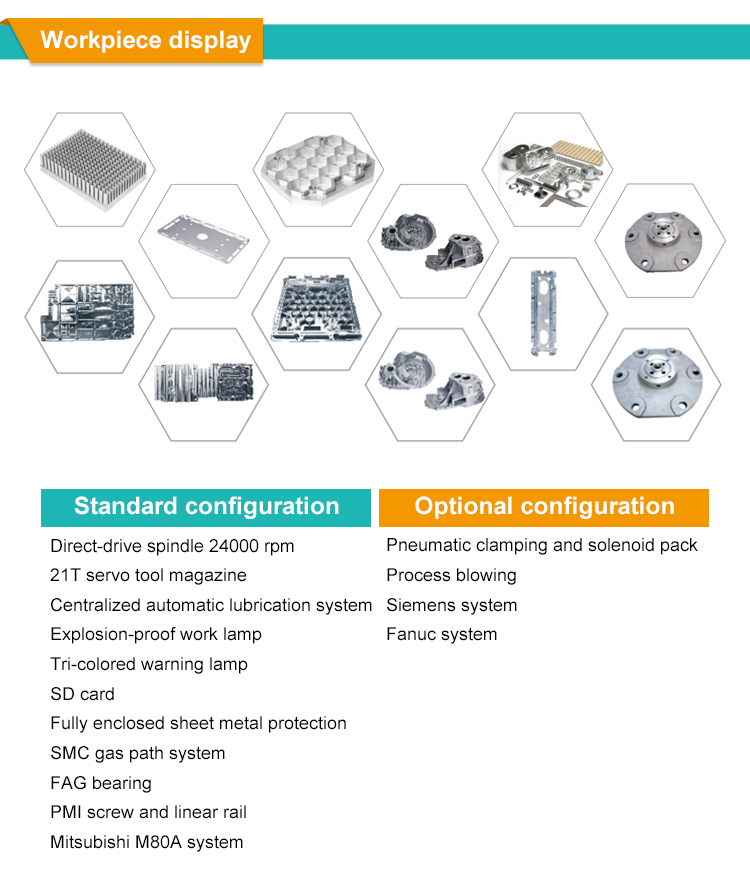

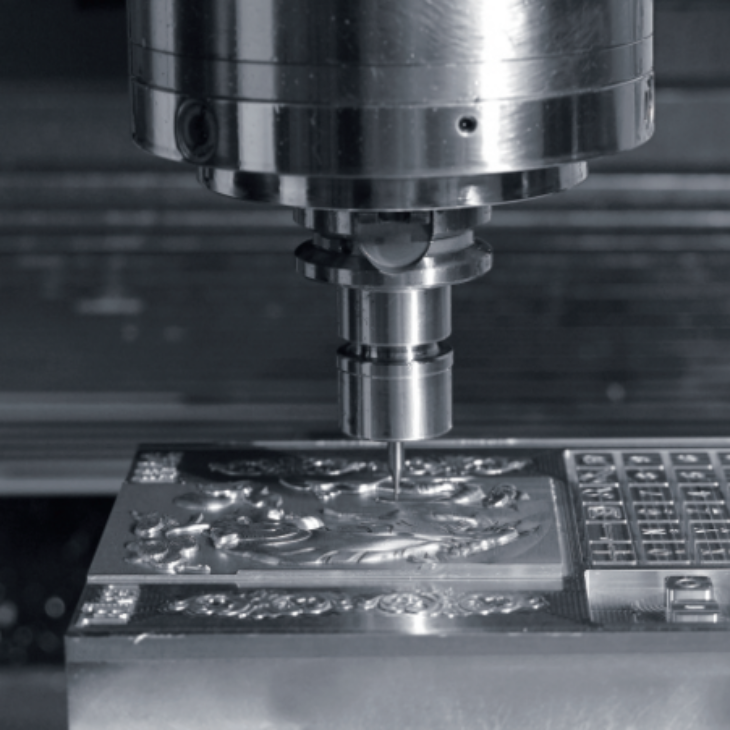

The screw of X/Y/Z axis all adopts precision ballscrew, the three-axis guide rails adopt precision linear guide rails; Three axes adopt absolute value servomotors, by using the high-performance CNC system to analysis and compensate the location of coordinates to realize the high precision of the machine; The spindle adopts high precision inline spindle, with direct-drive structure, the highest speed is up to 24000rpm; The castings adopt Meehanite casting process with complete heat treatment to eliminate internal stress. The machine which has high-precision、high-speed and high-rigidity characteristics and integrates drilling、 tapping and milling together is widely used in the processing of small plate pars、disc parts and shells in3C industry、auto parts industry、small molds processing industry、 medical apparatuses industry etc.

Application Area

Mainly used for 3 C of consumer electronics shell, stainless steel equipment, aerospace, automotive parts and equipment in the industry of small plate parts processing.

Product Parameter

Item | Unit | T-500S | ||

Traveling | X axis | mm | 500 | |

| Y axis | mm | 400 | ||

| Z axis | mm | 320 | ||

| The distance from spindle end face to working table | mm | 180-500 | ||

Working table | Working table size | mm | 620*400 | |

| Max. loading | Kg | 250 | ||

Spindle | Spindle power | kw | 2.2/3.7 | |

| Spindle torque | N.m | 7/17.7 | ||

| Spindle speed | rpm | 20-24000 | ||

| Spindle dia. | mm | Ф100 | ||

| Spindle taper | / | BT30 | ||

Guide | X axis | / | 25 | |

| Y axis | / | 30 | ||

| Z axis | / | 35 | ||

Speed | X/Y/Z feeding rate | mm/min | 1-15000 | |

| X/Y/Z rapid speed | m/min | 48/48/48 | ||

Accuracy | Positioning accuracy | mm | 0.006 | |

| Repeatability | mm | 0.004 | ||

Tool | Tool magazine capacity | / | 21 | |

| Max. tool weight | kg | 3 | ||

| Max. tool length | mm | 200 | ||

| Max tool dia.(with/without adjacent tool) | mm | Ф60/Ф80 | ||

Others | System | / | Mitsubishi M80A | |