HMC Double Worktable CNC Horizontal Machining Center

HMC Series Double Worktable CNC Horizontal Machining Center, 4 axis milling machine center, CE, ISO Certificate

Send InquiryProduct Detail

Product Description

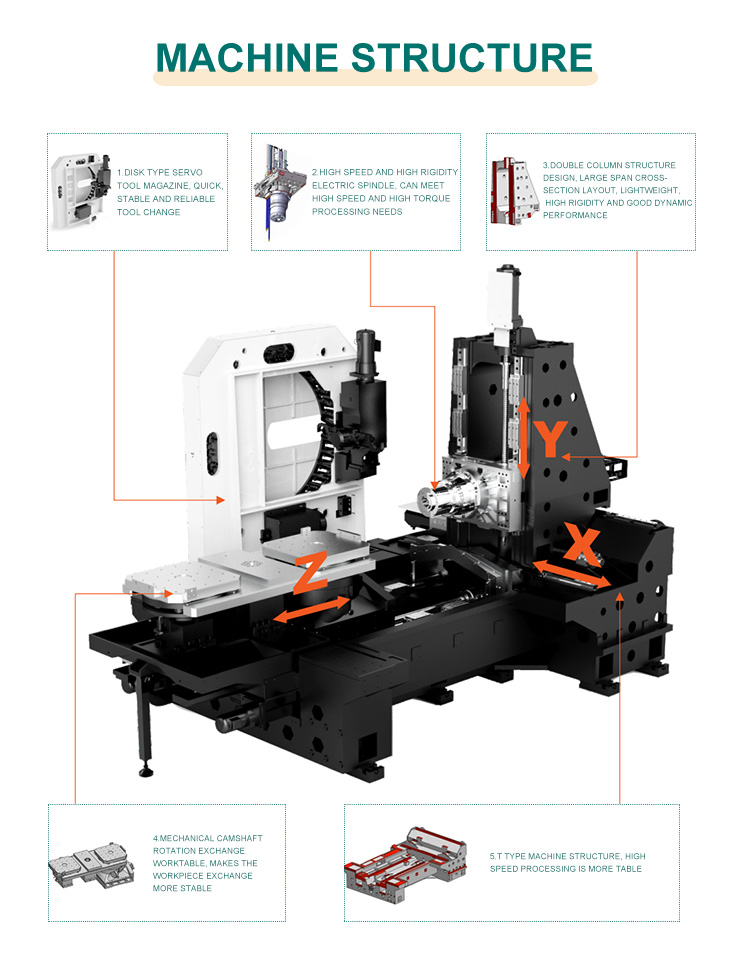

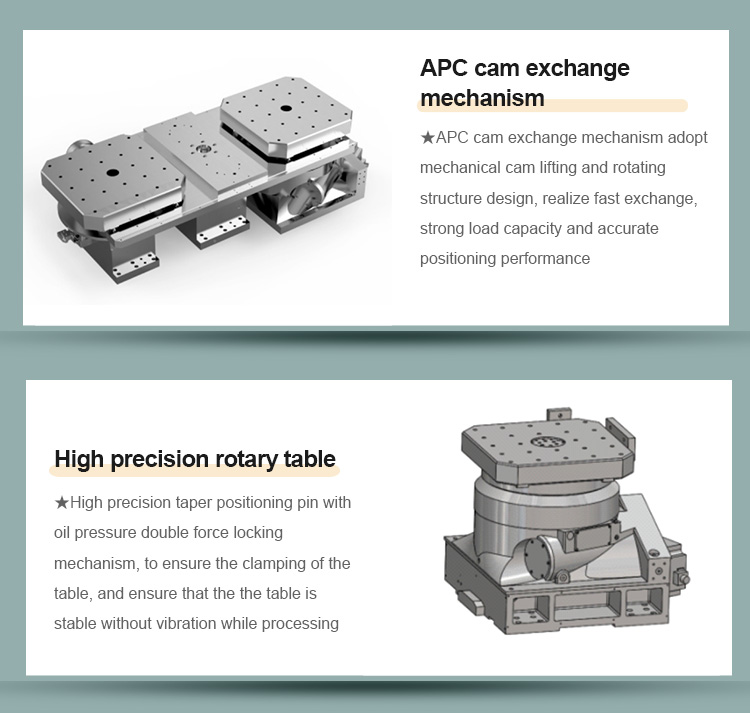

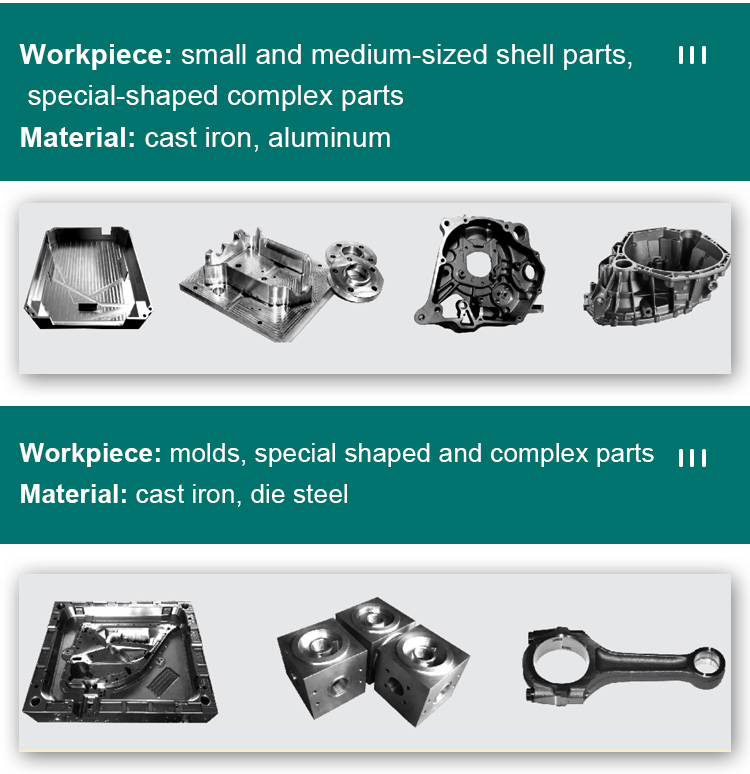

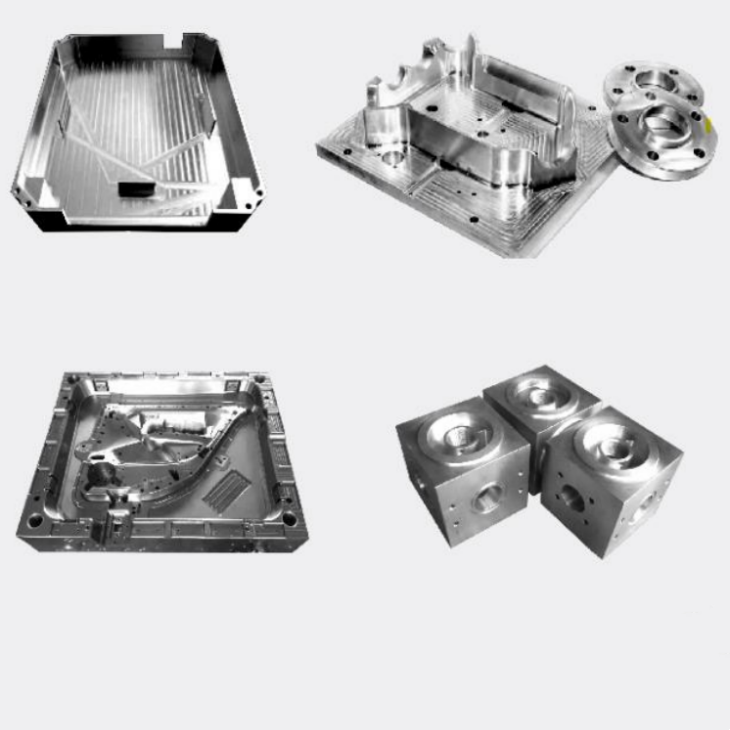

HMC-63 Horizontal Machining Center with Double Exchanging Worktables is mainly used for machining parts in construction machinery, automobile, IT, energy, mold and other industries. It is especially suitable for processing all kinds of special-shaped parts and box parts. One clamping of the workpiece can complete milling, drilling, boring, reaming, countersinking, tapping and other processes, which can effectively improve the efficiency and save the cost. At the same time, it can reduce the accumulated error caused by multiple clamping of the workpiece and improve the machining accuracy. The machine tool adopts a positive T-shaped structure, the column moves left and right (X axis), the headstock moves up and down (Y axis) and the worktable moves back and forth (Z axis), and is equipped with a double exchange rotary worktable and a large disc servo tool magazine.

Product Parameter

Item | Unit | HMC-50 | HMC-63 | HMC-80 | |

Traveling | X axis | mm | 750 | 1050 | 1400 |

| Y axis | mm | 700 | 800 | 1200 | |

| Z axis | mm | 750 | 1000 | 1350 | |

| The distance from spindle end face to working table | mm | 150-900 | 150-1150 | 150-1500 | |

| Max. workpiece size | mm | φ650×900 | φ930×1000 | φ1300×1450 | |

Working table | Working table size | mm | 500×500(Double worktable) | 630×630(Double worktable) | 800×800(Double worktable) |

| Max. loading | kg | 500 | 1200 | 2000 | |

| Min. setting unit | Deg(°) | 0.001 | 0.001 | 0.001 | |

Spindle | Spindle power | KW | 15/22 | 26/37 | 26/37 |

| Spindle torque | N.m | 45.7/73.6 | 305/512 | 305/512 | |

| Spindle speed | r/min | 100-15000 | 80-8000/80-10000(optional) | 80-8000/80-10000(optional) | |

| Spindle taper | BT40 | BT50 | BT50 | ||

Speed | X/Y/Z feeding rate | mm/min | 0-15000 | 0-15000 | 0-10000 |

| X/Y/Z rapid speed | m/min | 32 | 48 | 36 | |

Tool | Tool magazine capacity | BT40-60T | BT50-40T | BT50-60T | |

| Max. tool weight | kg | 8 | 20 | 20 | |

| Max. tool length | mm | 350 | 500 | 500 | |