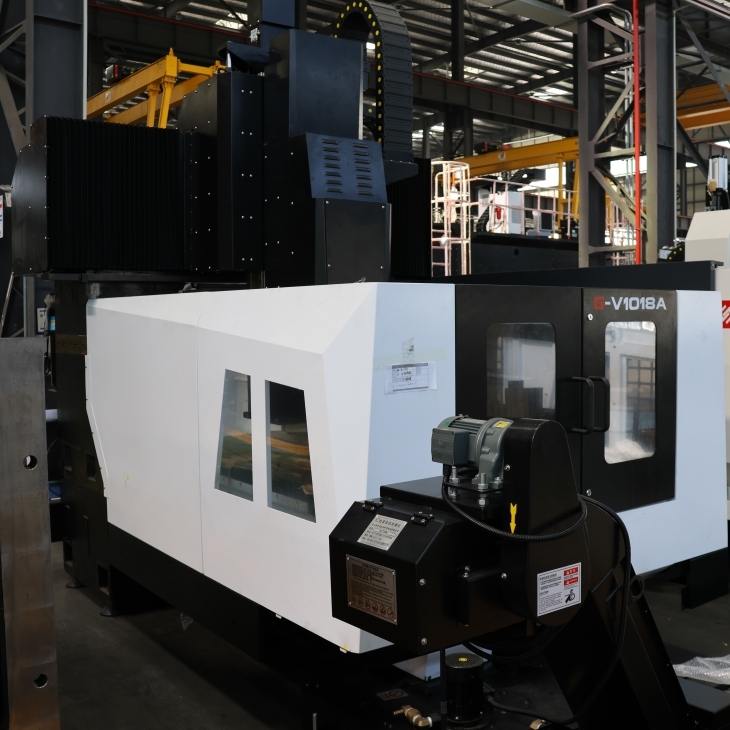

G-V1018 CNC Gantry Milling Machine Center

G-V1018 CNC Gantry Milling Machine Center, 3 axis milling machine center, CE ISO certificate

Send InquiryProduct Detail

Product Description

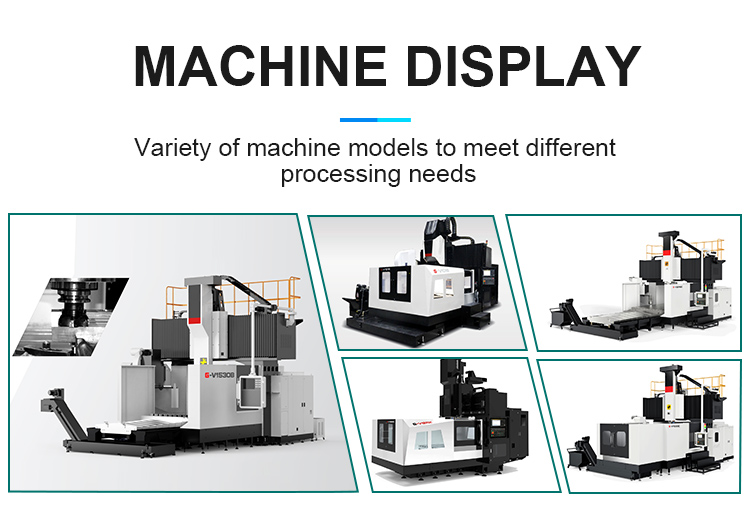

G-V series double column machining center includes series models

The integrated design of the column and beam has good rigidity, high machining accuracy and good stability;

The three-axis support adopts roller linear guide, which has fast dynamic response speed, high precision;

The three-axis feed is driven by the direct connection of the motor and the high-precision ball screw. The two ends of the screw are fixed with a pre-stretched structure, and the transmission accuracy is high;

The main shaft is equipped with a belt-driven BT50-6000rpm main shaft as standard, and can be equipped with gear heads and electric spindles to meet different processing needs;

Z-axis is equipped with nitrogen balance device, with good load characteristics;

The machine tool adopts double screw row and front chain plate chip conveyor;

This series of machine tools is mainly suitable for high-speed and high-precision machining of parts in industries such as automobiles, laser equipment, automation equipment, energy, rail transit, and molds;

Product Parameter

Item | Unit | G-V1018 A/B/C | G-V1220/1225/1230 A/B/C | |

Traveling | Worktable Travel (X axis) | mm | 1800 | 2150/2650/3200 |

| Spindle Travel (Y axis) | mm | 1100+100(Tool change travel) | 1500+25(Tool change travel) | |

| Ram Travel (Z axis) | mm | 800 | 800 | |

| The distance from spindle end face to working table | mm | 100-900 | 100-900 | |

| Available Gantry Width | mm | 1200 | 1600 | |

Working table | Working table size | mm | 1800*1000 | 2000*1250/2500*1250/3000*1250 |

| Max. loading | Kg | 3000 | 4000/5000/6000 | |

Spindle | Spindle taper | / | A,B:BT50; C:BT40 | A,B:BT50; C:BT40 |

| Spindle power | kw | A,B:15/18.5; C:11/18.5 | A,B:15/18.5; C:11/18.5 | |

| Spindle speed | r/min | A,B:15/18.5; C:11/18.5 | A:6000; B:6000; C:15000 | |

| Spindle torque | N.m | A:191/315; B:286/560; C:45.7/125 | A:191/315; B:286/560; C:45.7/125 | |

Speed | Speed of cutting feed | mm/min | 1000/1000/1000 | |

| X/Y/Z rapid speed | mm/min | 2000/2000/1600 | ||

Accuracy | Positioning accuracy(X,Y,Z) | No Raster mm | 0.02/0.015/0.015 | 0.02(0.02/0.025)/0.015/0.015 |

| Raster | 0.015/0.012/0.012 | 0.015(0.018)/0.012/0.012 | ||

| Repeatability | No Raster mm | No Raster mm | 0.01(0.011/0.015)/0.008/0.008 | |

| Raster | 0.008/0.007/0.007 | 0.008(0.011)/0.007/0.007 | ||

Tool | Tool magazine capacity | / | 24 | |

| Max. tool dia./length/weight | mm/mm/kg | Φ110/350/18 | ||

| Max tool dia.(without adjacent tool) | mm | Φ200 | ||

Others | System | / | FANUC 0I-MF(5); Mitsubishi M80; SIEMENS 828D | |

| Machine dimension(L*W*H) | mm | 4500*4250*3900 | 5000(6000/7500)*4500*4000 | |

| Weight(about) | Kg | 13500 | 14500/16000/18000 | |

Note:

1.A is belt transmission spindle

2.B is all-geared transmission spindle

3.C is electric transmission spindle